3D Printing: Pen Holder

3D printing has a wide range of applications in fields such as arts, engineering, robotics, architecture, medicine, and more. As in-home 3D printers become more affordable, the popularity of 3D printing with hobbyists is growing.

After careful consideration, my choice fell on Creality Ender-3 V3 SE as it is cheap, beginner-friendly, provides good printing quality, easy to set up and use. Auto bed leveling eliminates the need for manual calibration, which can be frustrating for beginners. Assembly is not complicated and takes up to 30 minutes. After assembly and completing bed leveling, it is ready to go.

"Boat" is a popular model for benchmarking printing quality:

When making a pen holder model, I used Blender, a popular free 3D modeling software. This software has an option for saving models in STL format, which is required for slicing software such as Cura. Also, there are other options for model creation using CAD applications, like Autodesk Fusion 360, Shapr3D, Onshape, FreeCAD, etc.

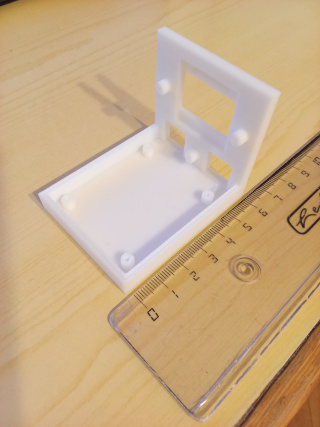

A casing prototype for my previous clock project was created by using Onshape:

For slicing software, I used UltiMaker Cura, an open-source slicing application for 3D printers. It needs to be configured for the particular 3D printer and filament.

I used Polymaker PolyTerra PLA Wood Brown as a filament for this project. In the software, I selected the "generic PLA" filament option, standard quality, and made some slight changes to the settings:

- Material

- Printing temperature - 210 ℃

- Build plate temperature - 50 ℃

- Speed

- Print speed - 80 mm/s

- Cooling

- Fan speed - 20%

Manufacturers often indicate printing and build plate temperatures, and occasionally printing speed, on filament spools. When printing medium-quality prints, it is common to use a printing speed for PLA of 40 to 60 mm/s, although it can go as high as 150 mm/s.

The recommended fan speed for PLA printing is 100%, but lowering the number makes the print more durable as inlayer bonds go stronger due to slowed filament temperature drop. But it can drastically lower print quality.

It is recommended to determine the optimal printing settings through experimentation. This involves testing different settings and configurations to achieve the desired balance between print quality and durability.

The print took almost 9 hours to complete. In my opinion, the surface has a nice texture and does not require any post-processing treatment:

Here is an STL file of the pen holder for you to print: